Slideway protectors (FBS)

Robust and incredibly fast

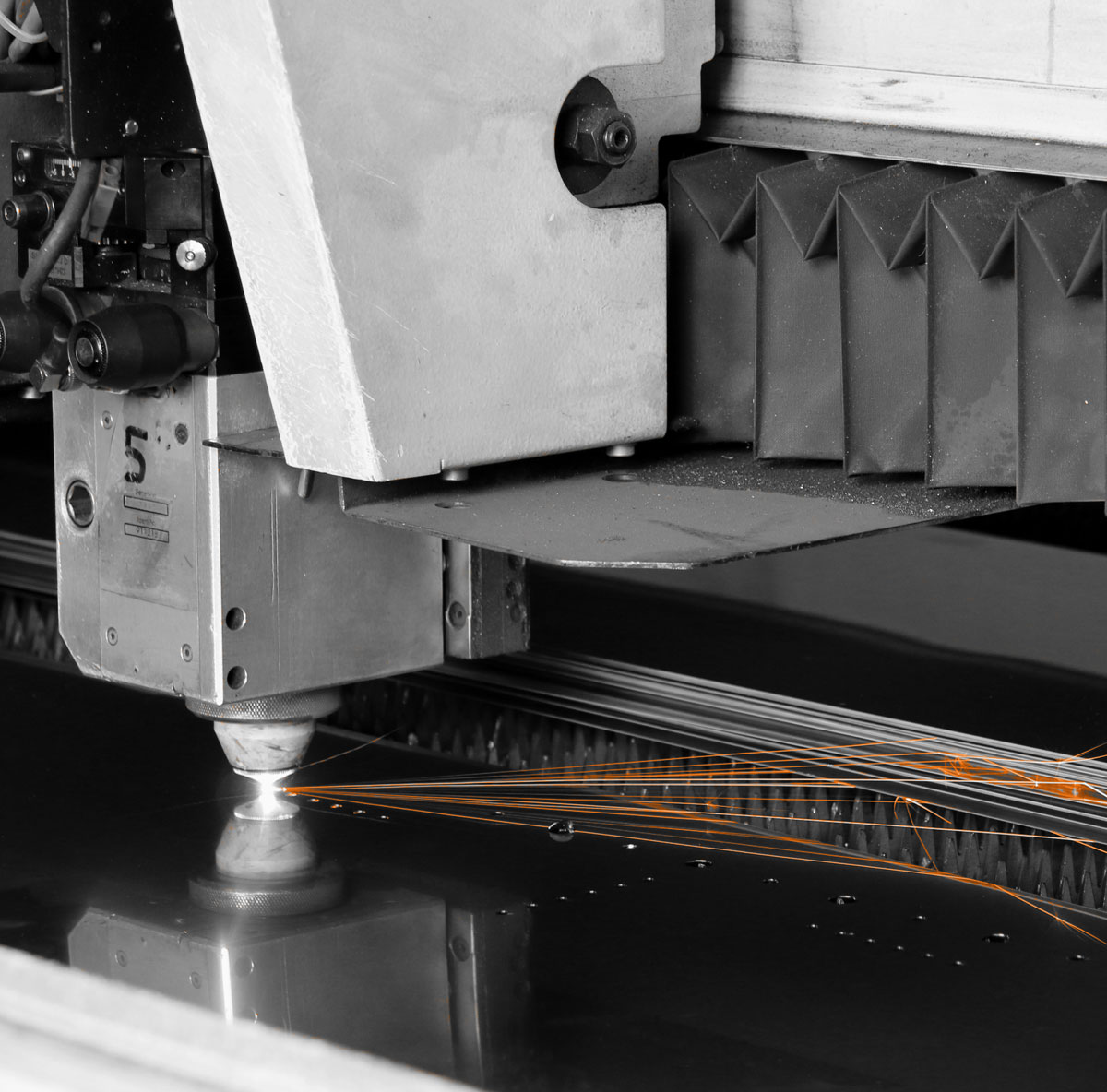

Slideways on machines need reliable protection against external contamination. innoFlex slideway protectors (FBS) cover these sensitive machine parts flexibly and follow the linear motion of the slideway – even during extremely dynamic, high-speed processing.

And machine operators are well protected from injury at the same time.

The design

innoFlex slideway protectors are made of highly resilient, coated special fabric. CNC-manufactured support frames in each fold give the cover reliable stability. The frames can be thermally bonded, welded or sewn to the covering fabric, depending on requirements.

Geometrically shaped guide frames reliably prevent any possible lifting from the slideway. Even at high processing speeds, our frame-supported slideway protectors run smoothly and without deviation.

innoFlex slideway protectors are available with pleat depths of 10 to 50 mm (in 5 mm increments). Specially designed sizes can also be arranged. Slideway protectors are available in a broad range of shapes and sizes – and can be installed in any position: horizontally, vertically, diagonally or even upside down.

innoFlex supplies its slideway protectors ready for installation with metal flange or Velcro fastenings. On request, customer-specific hole patterns can also be incorporated.

The protective functions

innoFlex slideway protectors safeguard machine parts from …

- Dirt and dust

- Wood and metal chips

- Water

- Oil and grease

- Cooling emulsions

- Welding spatter

- Grinding sparks

… and people from injuries

Special design: the folding toe guard

If machine components only need to be protected from one side, the innoFlex folding toe guard offers you a cost-effective alternative to the multi-sided slideway protectors.

innoFlex folding toe guards are available

- Without support frame for simple, extremely light covers with small block dimensions

- As a stable design with support frame

Folding toe guards tend to bulge when folded and should be guided by the customer, e.g. via a U-profile.

Reasons to choose slideway protectors from innoFlex:

- Excellent dimensional stability, even under heavy loads

- In addition to the U-shaped version, slanting designs are also available

- Precision support frame, CNC-manufactured

- Runs optimally, even for dynamic, high-speed processing

- Smooth running due to noise-reducing sliding components (optional)

- Highly tear-resistant fabric

- Precision folding

- Very thin materials available on request for low speeds and to reduce weight

- Special equipment for extreme loads available

- Suitable for ambient temperatures from –15 °C to +60 °C

- Water- and dustproof (except sewn versions)

- Customised mounting

- Easy to install

- Maintenance-free